Moor Fabs provides a complete plastic fabrication solution, from prototype parts to full-volume production. You can rely on our quick quotes and expert design services, plus our fast turnarounds on bespoke projects and batch production runs.

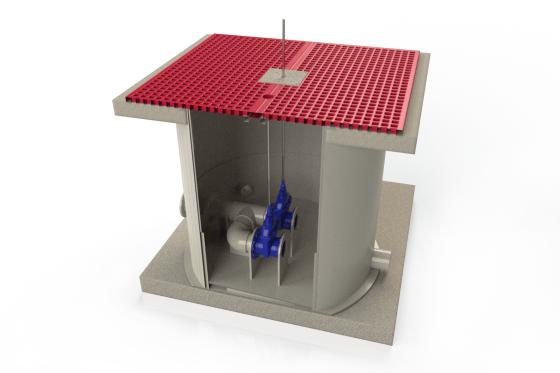

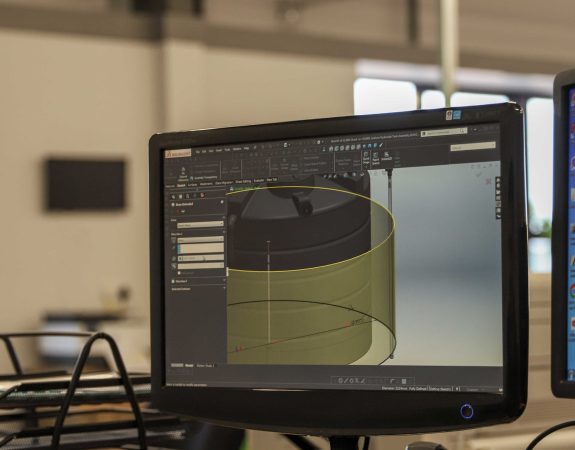

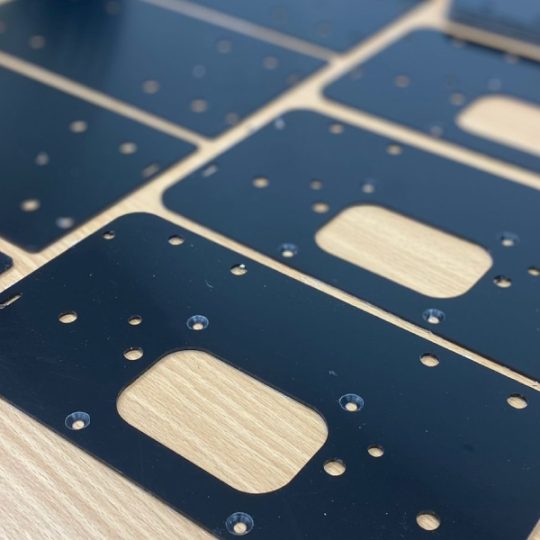

Our in-house capabilities include thermoplastic welding, plastic pipe fusion, plastics machining, CNC routing and 3D CAD. We apply these skills to produce our core products – chemical containment solutions (such as dosing cabinets), storage tanks, piping systems and fume extraction. Plus, we have the experience to design and manufacture completely unique industrial products, so we are always willing to take on new challenges.

We also have a dedicated site-installation team, who specialise in plastic pipeline installation, repairs to existing plastic equipment and the on-site fabrication and commissioning of our products.

Please explore our website to learn about more our capabilities, the industries we serve – and how our team can help you.

Plastic Fabrication - from Concept to Installation

Moor Fabs is proud to offer our dynamic, turnkey solutions to both our domestic partners and worldwide markets. From a new tank for your plating shop, to dual containment systems for your water treatment works, we can offer support from the design phase all the way through to product installation. Fabrication